Medical device manufacturers

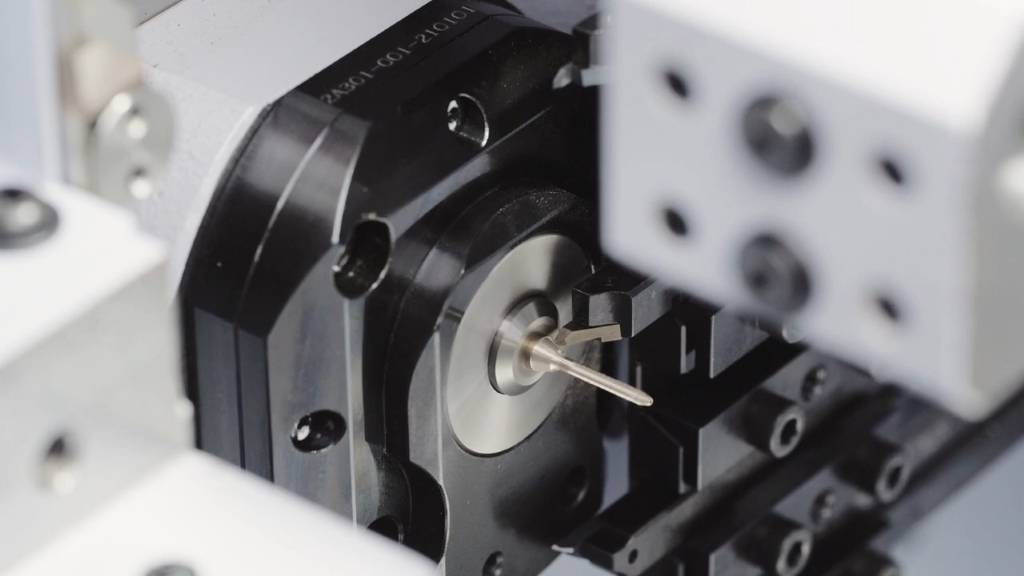

As leading UK medical device manufacturers and CNC machining experts, Oracle Precision is the ideal choice for your contract and subcontract medical device manufacturing requirements.

ISO 13485 Compliant Medical Device Manufacturing

We are an ISO 13485 compliant medical device manufacturing company with extensive experience working within industries where quality and safety are truly critical. Our team of precision engineers are therefore well versed in stringent compliance requirements, the necessity for adherence to close tolerance work, and a strong understanding of end user requirements for surgeons and patients alike.

Our History as Medical Device Manufacturers

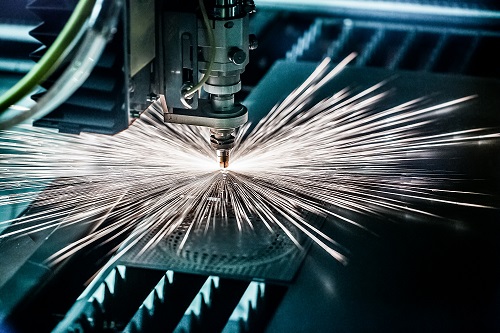

Oracle Precision was established upon a solid background within the precision medical engineering sector, with a focus on the manufacture of reconstructive medical devices, alongside associated instrumentation and ancillary components. From stainless steel and titanium to medical polymers, elastomers, and composites, we work with a range of materials in our medical CNC machining work.

As our work in medical engineering and manufacturing has progressed, Oracle Precision has continuously invested in state of the art facilities and capabilities. Furthermore, our Quality Management System is fully compliant with the international ISO 13485 standard for the manufacture and supply of medical devices. We are dedicated to ensuring best practice and uniform quality is maintained in everything we do, from device design and production to component inspection and lifecycle management.

We are proud to work with our medical engineering clients as contract and subcontract machinists at many key stages, as this ensures a systematic approach to quality and risk management for the devices we are involved in creating. Our services as medical device manufacturers include: